Work Orders

Contents

Work Orders

This chapter deal with the processing and use of work orders in the system.

Introduction to Work Orders

Work Orders within Agility are ‘Task-based’ and must contain at least one task. This means that a work order is essentially a ‘project’. Individual tasks can then be created within a Work Order. It is these tasks that are scheduled to employees rather than the work order as a whole. Therefore, if a Work order contains three tasks, then all three tasks will require scheduling to employees.

In situations where multiple tasks are not required, Agility includes the facility to create Single Task Work Orders. This allows rapid work order creation whereby the task record for the work order is created automatically.

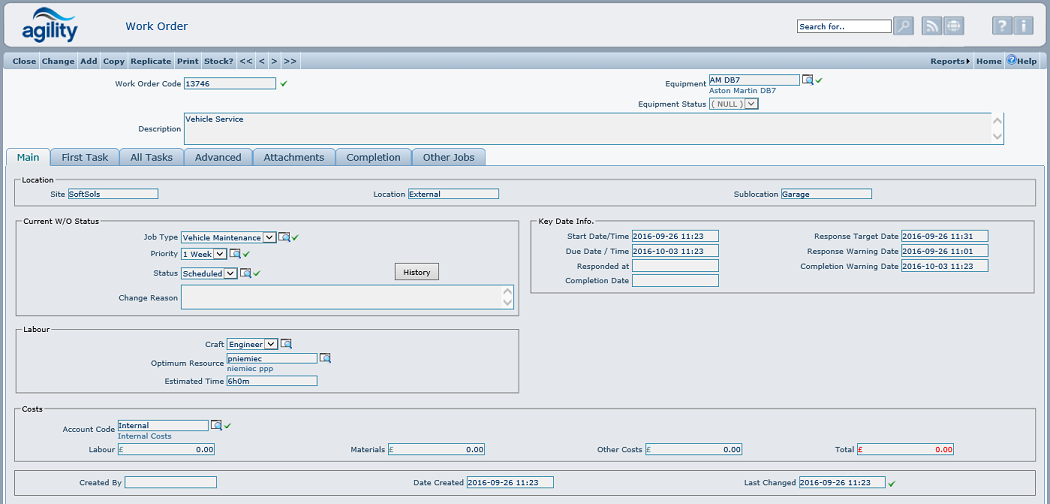

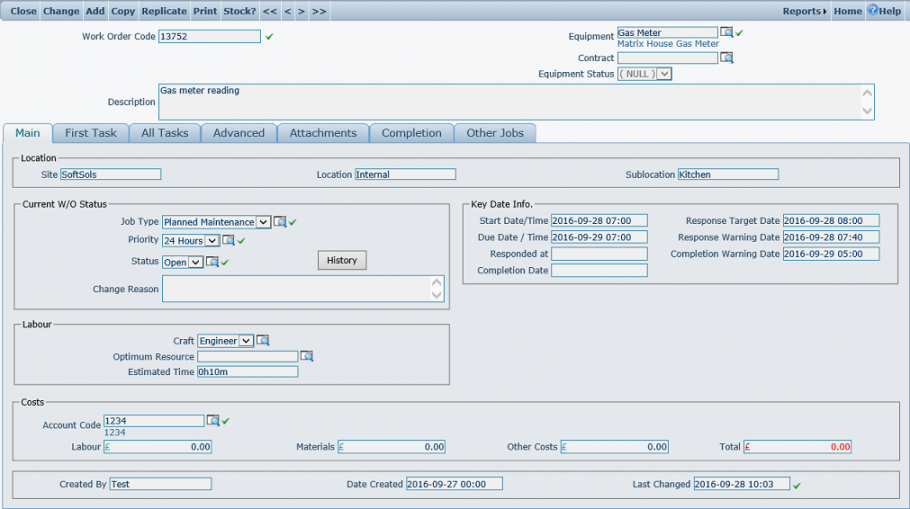

Work Order Detail

Individual work orders are viewed added and edited using the work order detail form. This can be accessed from ‘Add A New Work Order’ on the menu or from various main and inline scan grids using the detail drill down options.

Above: Typical example of a fully populated work order detail form in enquire mode.

Work Order Header Detail

Work Order

This field is read only and displays the Work Order Code. It is auto-generated when the work order is saved. The format of the Work order code is defined in the Sequence Definition for woJob.JobCode. Please refer to the Sequence Definitions section for details of how to amend the Work order Code format.

Equipment

This can be selected from the Equipment help Tree View or it can be input manually. This is a mandatory field. Work Orders cannot be created for equipment Items that have been taken out of service and have been flagged as obsolete.

Contract

This field is visible if system parameter "Contracting\ContractingInUse" = true and is automatically filled if all: StartDate, Asset, Craft and JobType are filled in and Contract has not been selected yet.

Description

This field is used to record a detailed explanation of the problem.

The remaining information that can be recorded onto a work order I then accessed via a series of tabs on the low pane of the form.

Main Tab

Location Box

Displays the Site, Location, Sub-Location (where applicable) for the Equipment that the work order is being raised against.

Current Work Order Status Box

Job Type

This combo-box is populated from the Standing Data file Work Order Types. This is a mandatory field.

If the Job Type selected is a Breakdown Job, then an additional box called ‘Breakdown’ will be displayed. This will allow the recording of a Breakdown date / time and Breakdown Reported date / time. This information will then be used by the system to calculate equipment down time. The Breakdown date / time and Breakdown reported date / time must be entered before a Breakdown Work Order can be created.

Priority

This combo-box is populated from the Standing Data file Priority Codes. This is a mandatory field

Status

This is used to specify the current status of the work order. The work order Status combo box shows only those statuses that have been set up in the System Parameter “InitialStatuesList”. This is a mandatory field.

Status Change Reason

If the status is changed then the field Status Change Reason must be filled in if the parameter StatusResReq has been set (see System Parameters). By default, this option is set to mandatory. Changing the status creates an entry in the Status History. Please refer to the section enquiring on Work Orders for details of how to view the work order status history.

Craft

Select the Craft required to carry out the work form the Craft drop-down list.

Optimum Resource

Selecting the Optimum Resource will change the Work Order Status to Scheduled. However, this indicates a preferred labour resource. This will be shown in the scheduler, but it will still be possible to schedule the task to someone else.

The Resource can be entered manually or selected from the help form.

Estimated Time

This is the estimated time that the task should take to compete. This duration is used in the Scheduler when scheduling the task to a Labour Resource.

At this stage the work order could be saved and a Work Order Number generated. The details entered into the Craft, Optimum Resource (Employee) and Estimated Time fields are used to automatically populate a task (entitled TASK01). This task can then be scheduled to Labour within the Task Scheduler. However, if a more complex Work Order is required, then the All Tasks grid can be used to define multiple detailed tasks.

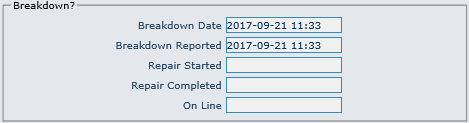

Breakdown Dates Info

If a work order type that is marked as a breakdown is selected then additional date options become available.

These dates are used for recorded and subsequent analysis of breakdown repairs, specifically in items such as MTBF and MTTR reports.

Breakdown Date

This is the date and time that the break down occurred.

Breakdown Reported

This is the date and time that the breakdown was reported.

Repair Started

This is the date and time that the repair work actually started.

Repair Completed

This is the date and time that the repair work was actually completed.

On Line

This is the date and time that the equipment was brought back on line. This can be different to the time the repair was actually completed dependant on procedures and protocols that may be in place.

By default none of these fields are mandatory.

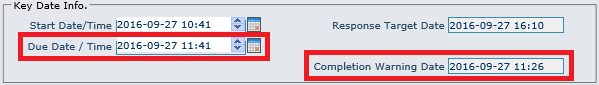

Key Date Info Box

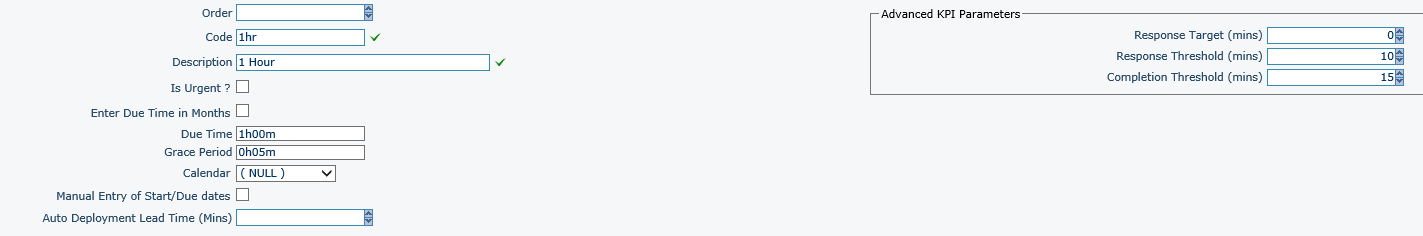

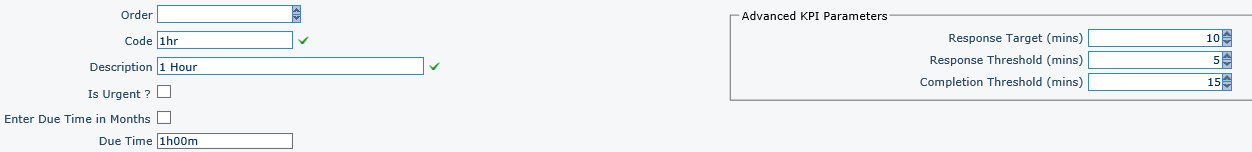

The dates within the info box will change dependant on the priority selected on the work order. If the priority has got response target, response threshold or completion threshold values set against it then the response and completion target and threshold values will be displayed. These are detailed below. (Response and Completion Targets and Thresholds)

Start Date / Time

On creation of a work order this will default to the current day and time. This can be manually adjusted.

Due Date / Time

If the selected priority has been set up with a ‘Due Time’ then the End Date / Time will be calculated based on the Start Date / Time and the Due Time. The Start Date / Time can be manually adjusted, the Due Date / Time will then recalculate.

Completion Date / Time

This field is read only. It records the date and time that the work order was completed

If the Work order is to contain only a single task, then the Craft, Optimum Resource (Employee) and Estimated Time fields can be populated. Otherwise, ignore these fields and use the All Tasks Grid.

Response and Completion Targets and Thresholds

These following three fields are not mandatory, are automatically calculated by the system and can be used to produce KPI charts and scan forms that can display work order status conditions, i.e. a work order is approaching due date time or a work order has not been responded to within the target time, or the work order response target is approaching. These can then be used to assist in prioritising work load to ensure that SLA targets are met.

Response Target Date /Time

If the priority selected has got the Response Target field populated, this date will be automatically calculated as the current date/time plus number of minutes filled in the Response Target field.

Response Warning Date /Time

If the priority selected has got the Response Threshold field populated, this date will be automatically calculated as the Response Target minus number of minutes filled in the Response Threshold field.

Completion Warning Date /Time

If the priority selected has got the Completion Threshold field populated, this date will be automatically calculated as the Due Date minus number of minutes filled in the Completion Threshold field.

Automatic Date Changes

The responded at and repair started at dates are modified automatically when any of the following transactions occur against the work order.

When an employee logs on to a work order (Agility)

Status update to ‘Arrived on Site’ (Mobile Expert)

Status update to ‘Arrived’ (Mobile Lite)

Manual time entry against the work order (Agility)

The date will be modified in the following way;

Responded At Date: If the date in responded at is null or is after the date of the transaction listed above, the responded at date will be set to the transaction date. If responded at date is before the transaction date it will remain unchanged.

Repair Started Date: If the date in repair started at is null or is after the date of the transaction listed above, the repair started at date will be set to the transaction date. If repair started at date is before the transaction date it will remain unchanged.

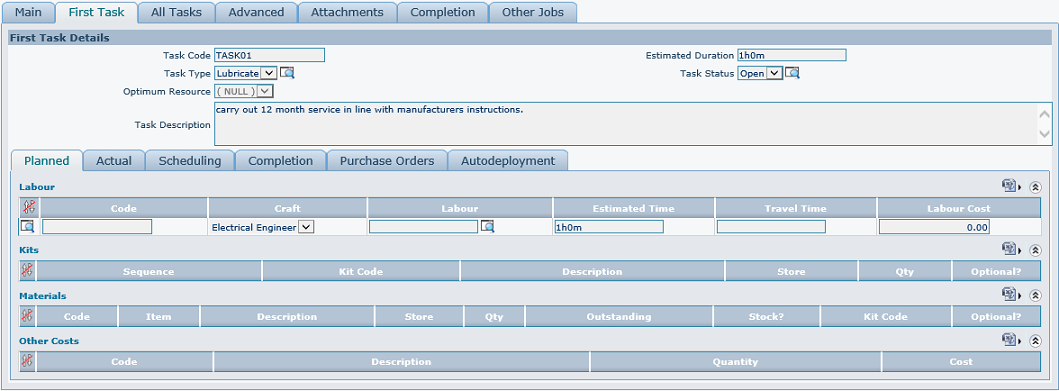

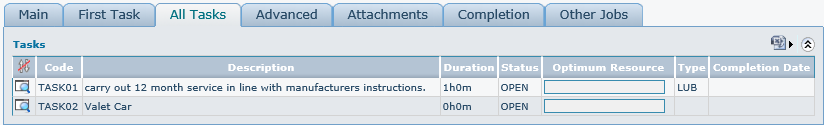

First Task and All Tasks Tab

The first task tab contains details of the primary work order task; in the event that the work order is using multiple tasks then this will be the first task.

If multiple tasks are used then all work order tasks can be accessed from the all tasks tab. The first task tab opens the task detail sub form directly, as shown below.

Example task Detail form

The all tasks tab open a grid that lists all tasks. From which each individual task can be drilled into.

When a task is drilled into using the view detail icon the task detail form will be opened for the selected task. A overview of the task detail form is given below.

Task Detail Form; (Also shown in the above screen capture)

This sub form is split into a header and a tabbed section. The header detail contains information on the work order task.

Tab Sections

Each tab contains sections relevant to the selected task.

Planned Tab

This contains grids that show the various planned labour resources, material and other costs expected to be incurred on this task.

Actual Tab

Like the planned tab this grid contains details of labour resources, material and other costs but is where the actual usage is recorded.

Scheduling Tab

This shows which employee has been scheduled to which task, the status of the task and labour activity in terms of logging on to and logging off from a task.

Completion Tab

This is where the task completion details are recorded.

Purchase Orders

This shows details of any purchase orders that are associated with this task. For more information on direct purchase please refer to the purchasing chapter.

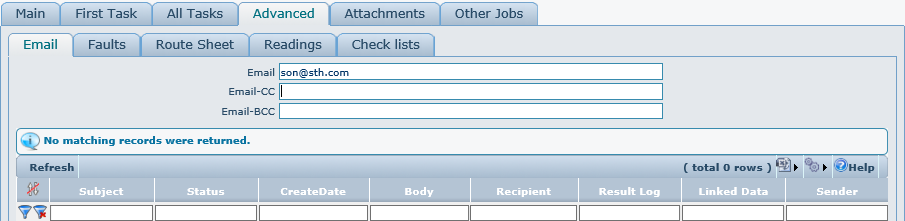

Advanced Tab

The advanced tab provides access to extended work order functions each of the functions is accessed via a sub set of tabs.

E-Mail Tab

E-Mail recipient addresses can be manually added to a work order. These can be used to trigger a mail to be sent to notify a contact of events occurring to the work order, such as a status change. These fields are additional to those specified against the Equipment Record.

Notifications are generated based upon triggers set against different criteria, i.e. if a work order status has a notification action specified then when the work order is changed that status a notification will be automatically sent to the listed recipients.

The lower half of the form contains a log of mail notifications that have been sent.

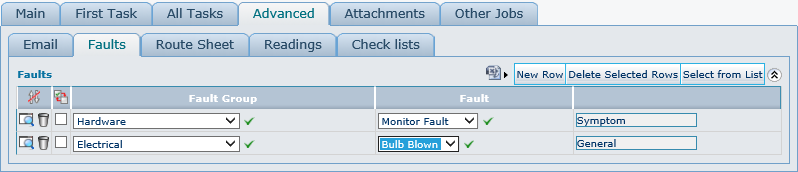

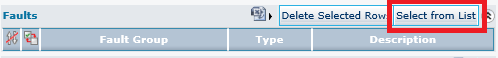

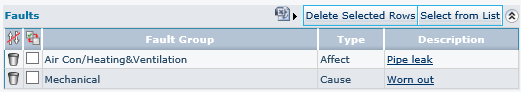

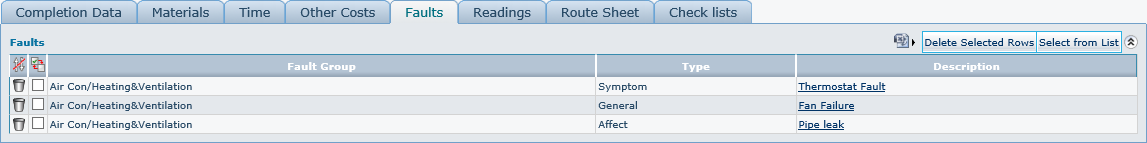

Faults Tab

Any fault codes recorded against the work order can be viewed or edited and additional ones added here. These fault codes are used for subsequent analysis in charts and reports available in other areas of the system. Faults can be recorded against a work order, using the log off, work order completion forms or manually through the work order detail form here, when in change mode.

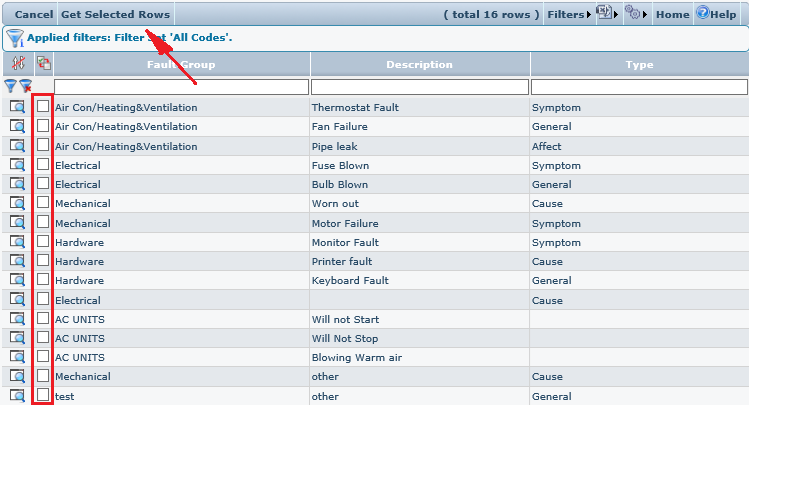

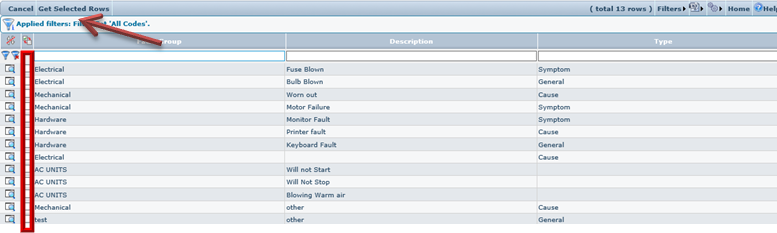

To manually add faults using this form when in change mode, click the new row option at the top of the grid and select the required options from the drop down selection lists. Or alternatively, click the select from list option. This will open a multi select grid of available faults that can be selected. Click the check box of the fault(s) that need to be added to the work order using the selection check boxes.

Once the selection has been made click the ‘get selected rows’ option to return the selected rows back to the grid.

To remove any individual recorded faults click the delete icon on the row of the unrequired fault code. Alternative select the unrequired rows by clicking the ‘select’ check box for that item Then click the delete selected rows option at the top of the grid.

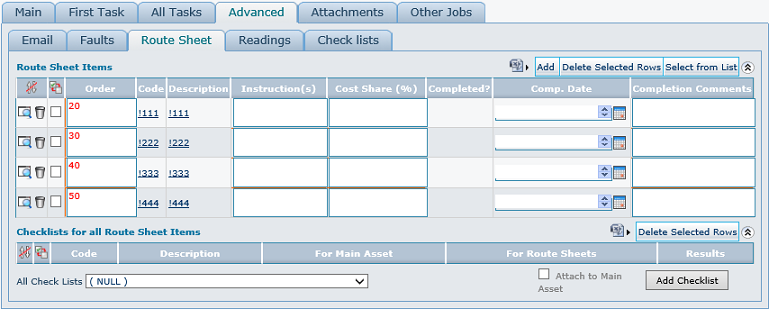

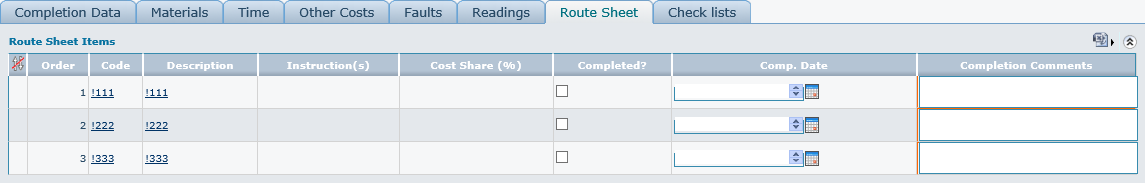

Route Sheet Tab

In circumstances where the same task is to be performed across a large number of equipment items, instead of creating one work order for each equipment item, use of a route sheet may prove more efficient.

A route sheet is simply a list of equipment items where the same tasks as described on the current work order need to be carried out. These are normally used for planned maintenance tasks. The list of items is accessed suing the route sheet tab.

Since route sheets are usually applicable to planned maintenance tasks then the list of equipment items is usually defined against the appropriate PPM schedule, the list is then used when the work order is created. The list would then be visible here.

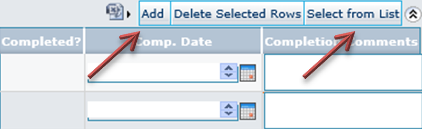

However items can be manually added to the work order route sheet manually. Items can be added individually or by means of selecting multiple items from an equipment selection list. The add function on the grid will allow addition of a single item via a detail form. The select from list option will open the selection list for the addition of multiple items, which can then be subsequently edited either within the grid row or by drilling into the detail form on each item.

Each route sheet item is made up from the following information;

Equipment

This is the equipment code of the item to be added to the list.

Instructions

Any additional instructions applicable to this specific item can be added here.

Item Order

The Item Order will be generated automatically however this can be manually adjusted to record the order in which the route sheet items should be dealt with.

Costing Share

The Costing Share field is used to determine what percentage of the overall Work Order cost is allocated against the Route sheet item. This is an integer field and does not allow decimal values. However it should be noted that that costing on route sheet items is subject to the configuration of system parameters and the value specified here may not be used dependant on configuration. This should be clarified with your system administrator.

The parameters are defined fully in the Standing Data chapter under system parameters. They are located in this path ‘ProcesMngt\RouteSheet’ and are called ‘LabourCostCalcType’, ‘MaterialCostCalcType’ and ‘OtherCostCalcType’.

*In the below definitions; ‘Overall work order cost’ refers to the overall work order cost applicable to the parameter.

LabourCostCalcType Overall Labour Cost

MaterialCostCalcType Overall Material Cost

OtherCostCalcType Overall Other Cost

Each parameter can be configured with one of the following settings;

BasedOnProportion

The percentage proportion of cost specified in the costing share on each item will be applied to that item. The cost assigned to the main equipment item which the work order has been raised against will be 100 % of the overall cost minus the sum of all cost proportions applied to list items.

For example;

If there are 2 route sheet items, one with costing share set at 35% and the other set at 25% and the overall cost of the work order was £1000.00. The costs would be allocated in the following way.

Main Equipment Item £400.00

First Route Sheet Item £350.00

Second Route Sheet Item £250.00

NoSplit

All costs incurred against the work order will be allocated against to the main equipment item. No costs will be applied to any route sheet items.

AllocatedToEach

The overall cost of the work order will be applied to each item on the route sheet as well as the main equipment item. For example if the overall cost of the work order was £500.00 then £500.00 will be allocated to the main equipment item and each route sheet item.

EvenlyAllocated

The overall work order cost will be evenly divided across the main equipment item and each of the route sheet items. The cost applied to each item is calculated by the overall cost of the work order divided by the number of route sheet items plus 1.

For example if there are 2 route sheet items, and the overall cost of the work order is £900.00 then £300.00 will be allocated against both route sheet items and the main equipment item.

Completed

This checkbox indicates if all tasks on the work order have been completed against this route sheet item. A checked state indicates complete.

Completion Date

This is the date that the tasks were completed against this particular route sheet item.

Completion Comments

Additional completion comments applicable to the completion of tasks against this route sheet item

It is not essential to complete all route sheet items to be able to complete the work order. If there are incomplete route sheet items when the main work order is completed then a warning message will be displayed allowing the completion process to be cancelled and the route sheet data to be amended.

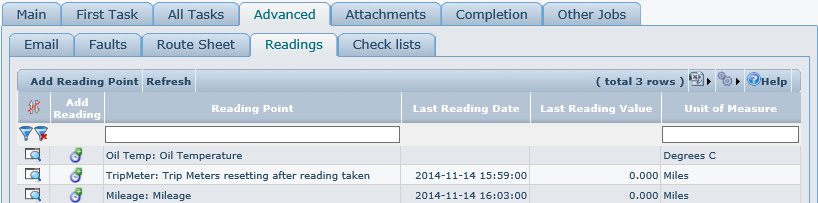

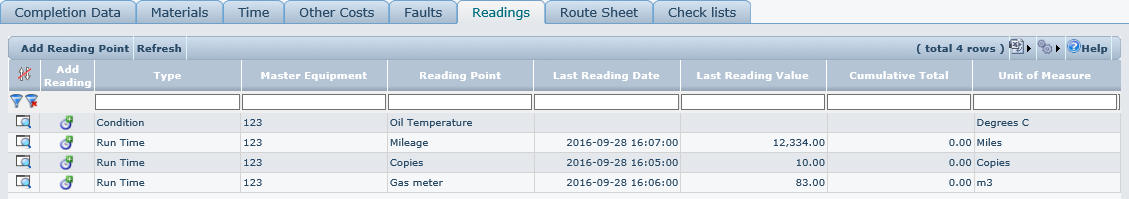

Readings Tab

Any meter reading points associated with any of the equipment items specified on a work order, either as the main equipment item or route sheet items will be accessible from the readings tab.

Reading taken during the execution of the work orders tasks can be recorded against the equipment item directly from here. The grid is same as the one used for normal readings entry. Detailed information on how to add readings using this grid can be found in the Equipment chapter under the ‘adding readings’ topic.

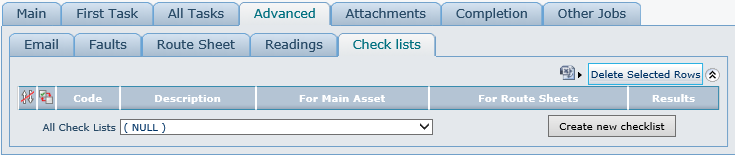

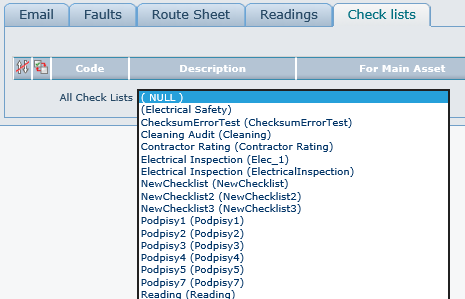

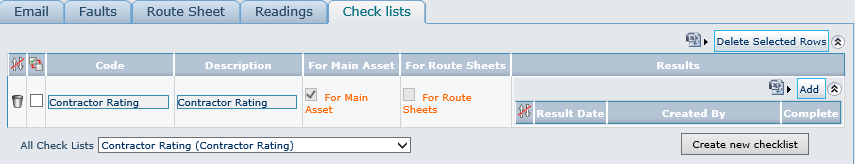

Checklists

Checklists are items that can be attached to a work order and are used to capture data using pre-defined questions or prompts. One or more checklists can be attached to a work order. The checklists are pre-defined in the system, for more information on defining checklists please see the Checklists and Work Order Types topics in the Standing Data Chapter.

Checklists can be completed from within agility or from a mobile device, if the checklist has been configured to deploy to mobile devices.

Checklists can be added to a work order manually or are automatically added if the work order type used has checklists attached.

To manually add a checklist to a work order, first select the required checklist from the drop down list of available pre-defined checklists. Then click the ‘create new checklist’ button.

A new check list will then be added to the work order.

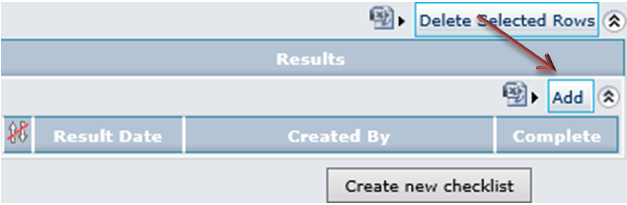

To fill in the checklist click the add button located in the results grid adjacent to the required checklist.

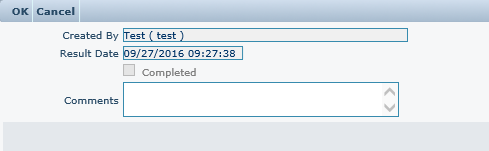

This will open the checklist in a new form. Each checklist consists on a simple header and a series of prompts or questions.

Header Values;

Created By

This is the user who entered the data. This will be automatically populated with the currently logged on user details.

Result Date

This is the date and time that the data was entered.

Completed

This flag is controlled by the system and will only complete when all mandatory items on the checklist have been completed. Mandatory items are marked with ‘*’. Dependant on the configuration of the checklist it may not possible to progress the work order to the next status in the work flow until the checklist has been completed.

Comments

This can be used to record any additional comments in relation to the results.

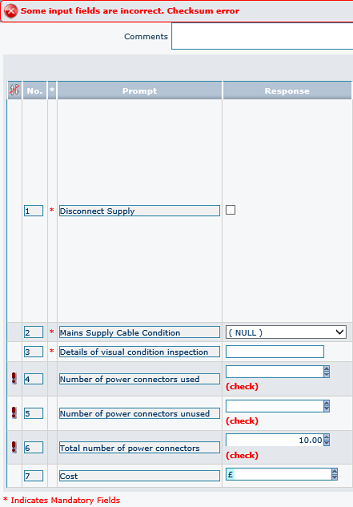

Below the header detail is a grid containing the check list pre-defined prompts or questions.

Data should be entered in the result column of the grid. The number of items, type of items and type of data that can be entered is determined by the pre-defined checklist. A sample checklist is displayed below.

Some checklists can be configured with a checksum validation. More information on this can be found in the Checklists topic of the Standing Data chapter.

When data entry has been completed and ok has been clicked, if the form returns a checksum error. The data entered should be checked for validity.

In the below example the total number of connectors used and the number of connectors unused does not equal the total number of connectors. So the form reports this as a checksum error.

Each checksum field involved will be indicated and the form cannot be saved until the checksum error has been resolved.

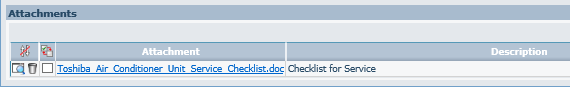

''''Attachments Tab

This tab contains a grid listing any files that have been attached to this individual work order. Files can be pre-attached to the work order if the work order was created using a standing job that has attachments defined or if the equipment item that the work order has been raised against has files attached. Additional files can be manually attached using this grid. These for example could be risk assessments, captured images, schematics etc.

Attachment

This is the physical file name, which is displayed as a hyperlink. The file can be downloaded and / or viewed from the system by clicking this hyperlink.

Auto Print

If this flag is checked then the attachment will be automatically printed with this work order. Note: While adding attachment on some forms i.e UOM this field is not presented.

To manually attach a new file, click the ‘add’ option at the top of the grid. The file attachment method is the same as described in the Common Functionality chapter under the ‘Attachments’ topic.

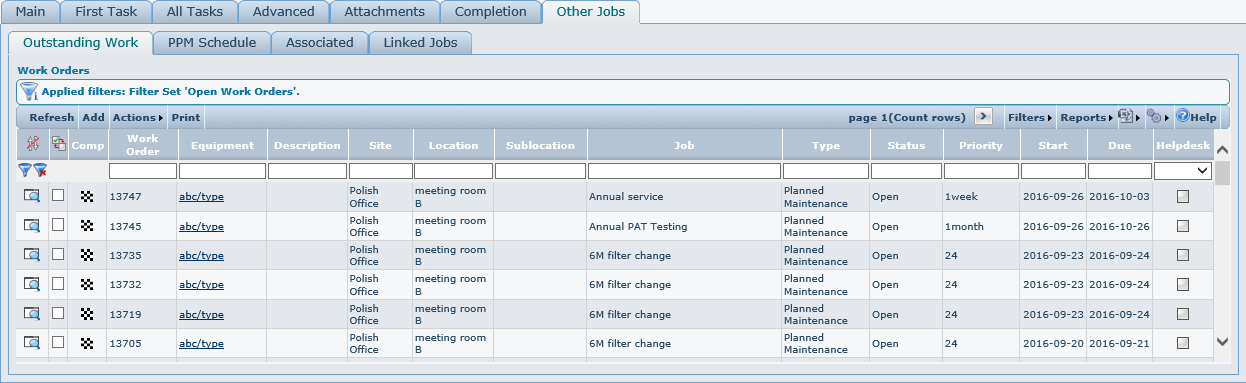

Other Jobs Tab

The other jobs tab contains a sub set of tabs that have information on works orders and planned maintenance schedules that exist against the main equipment item on the work order as well as information on linked jobs.

Outstanding Work Tab

This tab contains an in line version of the standard work order list form that contains a pre-filter so that it only shows any other outstanding work orders that have been raised against the main equipment item in the current work order. The operation of this grid is the same as described in the ‘Work Order List’ topic within this chapter. This grid allows a user to see if there are other outstanding works for the current equipment items that could be carried out at the same time as this work order.

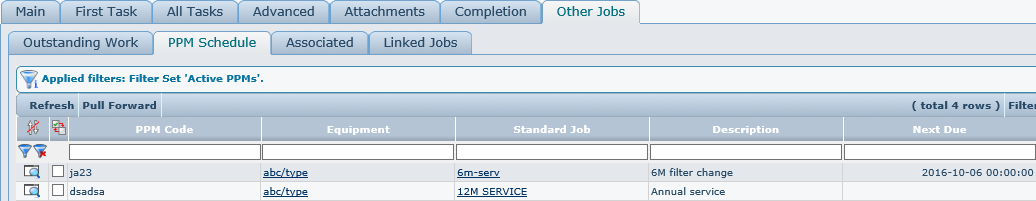

PPM Schedule

Within this tab a grid that details any PPM schedules that are defined against the main equipment item on the work order.

From here the user can view, manipulate and ‘pull forward’ any of the defined PPM jobs so that planned maintenance work can be undertaken at the same time as the current work order. For more information on the use and implementation of PPM schedules please refer to the ‘Standing Jobs’ chapter.

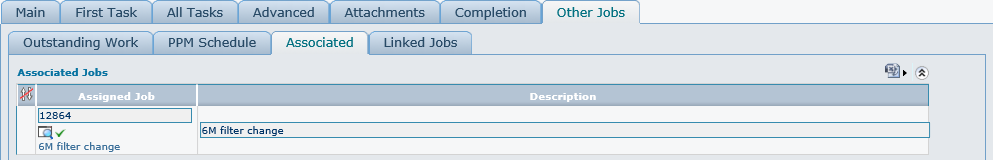

Associated Tab

This provides a method of creating an association between 2 or more jobs and viewing any currently associated jobs. Associating jobs provides, for example, the user with a view of any other work currently being undertaken that may have implications this particular work order.

The form is divided into 2 grids.

The upper grid shows that have been added as associated jobs to this work order. New job associations can be created here by clicking the ‘new row’ function at the top of the grid. To link another existing work order the user just needs to enter or select the work order number. Additional comments relevant to the association can also be added.

Field Definitions;

Associated Job

The is the number of the associated work order

Description

This is a free text description of the association.

The lower grid shows a list of any work orders which the current work order has been added to.

Field Definitions;

Associated Job

This is the number of the associated work order which the current work order has been added to.

Description

This is a free text description of the association.

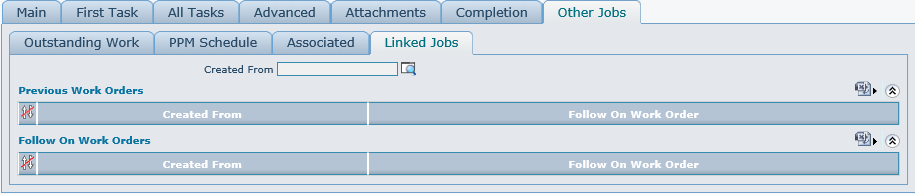

Linked Jobs Tab

The link jobs tab is similar to associated jobs but jobs, but in this instance it forms more of an audit trail of ‘follow on’ jobs. The tab is divided into 2 grids, the upper shows any previous jobs, if existing, that this job was created from, the lower shows if a follow on job has been created from this job.

The grid columns simply detail the linked work order numbers. A detail icon is provided to view the full detail.

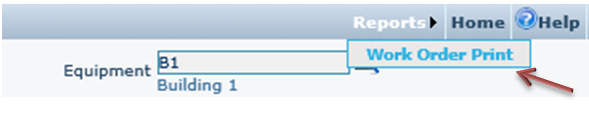

Printing Work Orders

There are 2 main areas within the system that work orders can be printed from. The single currently viewed work order can be printed from the work order detail form, using the report menu within the page header.

When printing the current work order from here the work order is first displayed in report preview mode. From here the work order can be exported to a word or PDF document and saved or printed.

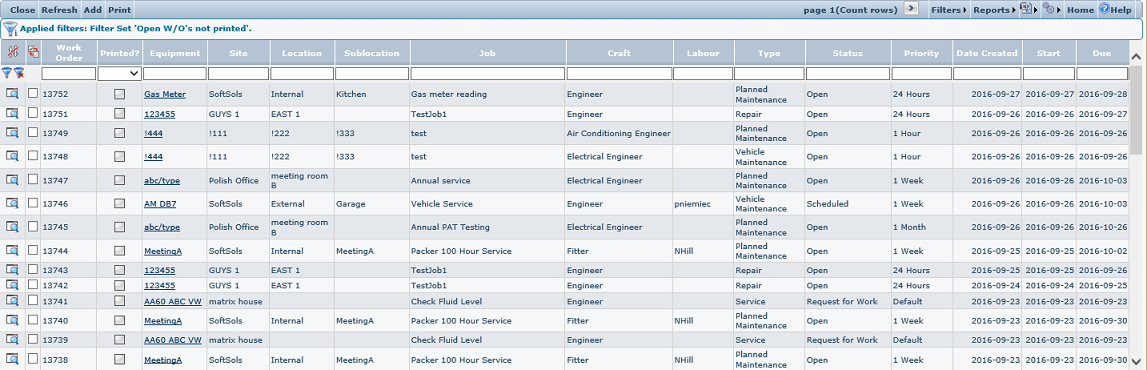

Multiple selected work orders can be printed from the work order print scan form that allows filtering and record selection.

Work Order Print

Accessed from Work Orders >> Work Order Print

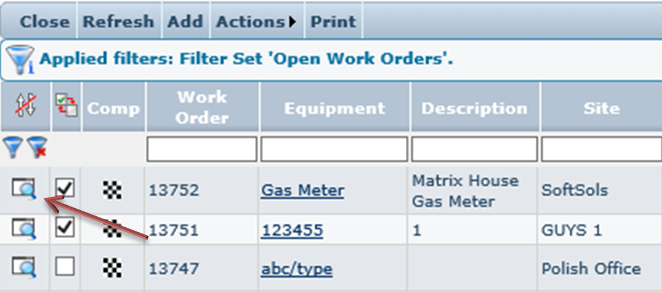

The form has been designed to allow multiple records to be selected. Using the scan form filtering row, selection criteria can be applied to any of the column visible.

Filters can be applied, as with any scan form and once the required works orders have been filtered, any of those displayed can be selected for printing by clicking the check box. Once the selection has been made the print option should be selected from the menu bar at the top.

This action will trigger the generation of a PDF document which will be made up of all selected work orders and any associated attachments, in order.

This document can then be saved for printing later, emailing etc. or the document can then be sent directly to the printer.

Each work order contains a flag that indicates if it has been printed. This flag is set to yes once the work order has been printed.

The work order layout will vary dependant on the template or design used for printing.

Work Order Scan & Tree Views

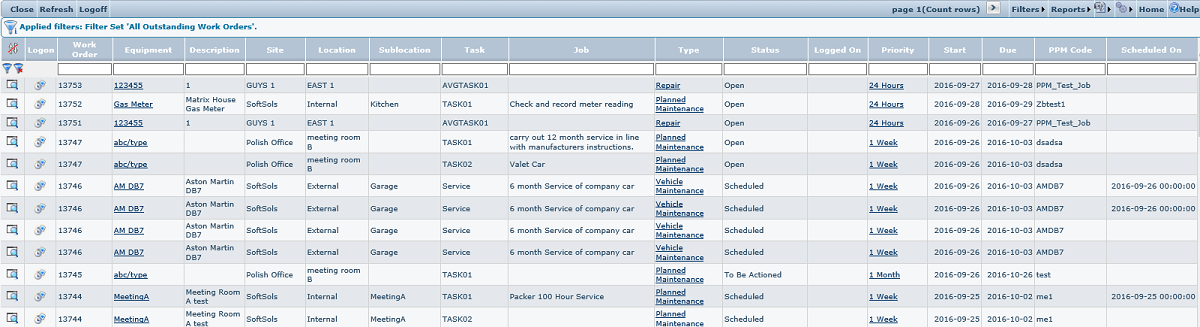

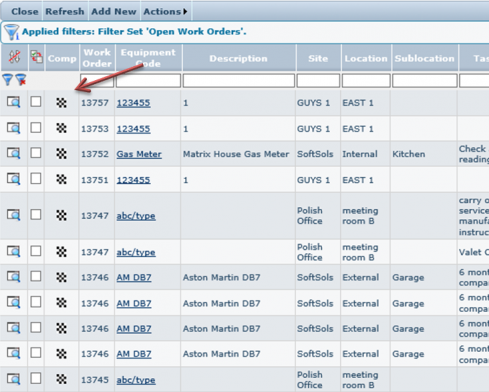

The system provides various scan forms and structured tree views with different options and methods of organising the work order data. Each of these scan forms also incorporates the standard set of controls provided with scan forms as detailed in the ‘Common Functionality’ chapter.

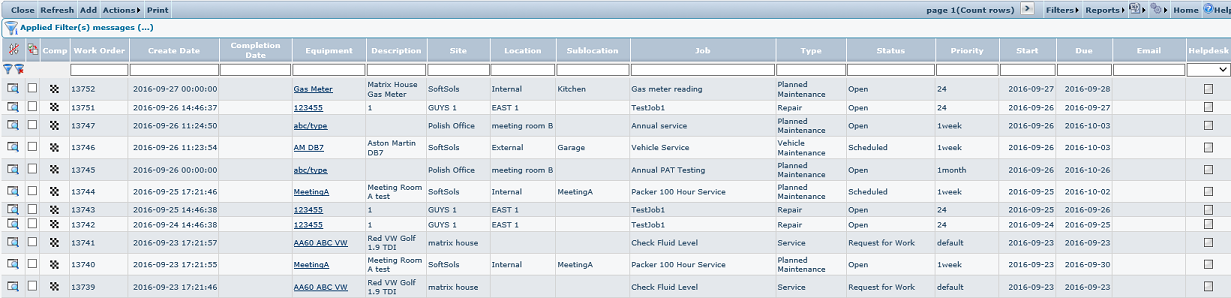

By using the Filter options in the menu bar of the Work Order Scan Form, it is possible to refine the selection of Work Orders displayed by assigning specific criteria to which the Work Orders displayed must conform.

If you are unable to find the record you are looking for then check the Filter Set that is currently active. The green tick identifies the filter set in use.

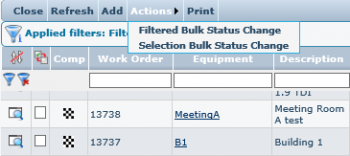

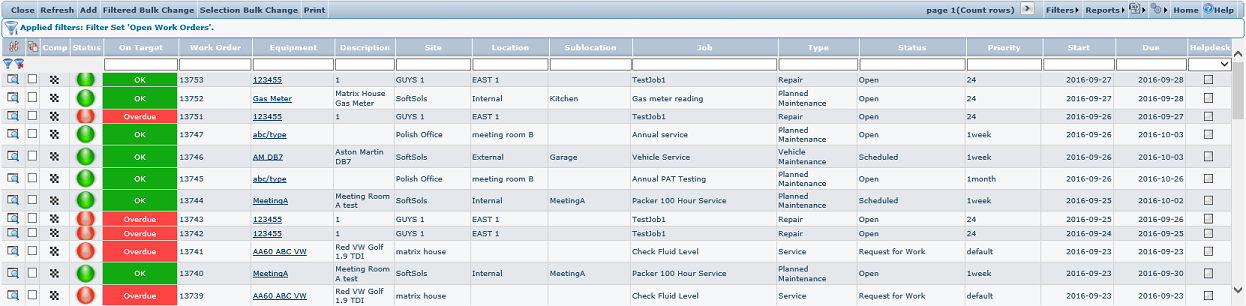

Bulk Work Order Changes

The majority of work order scans contain a bulk change option. These options provide a means of making a mass change to work order status on multiple selected work orders without having to change each individual work order. They can work on either a filtered set of work orders or on work orders which the user can select from the current filtered scan by clicking the selection checkbox on the required row.

Once the required selection has been made to access the bulk change select the required option from the menu bar. Dependant on which scan form is currently open the option may be displayed directly on the menu bar or within an ‘actions’ sub menu.

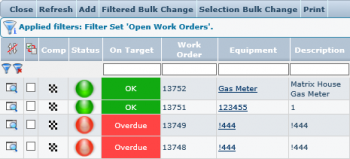

Above example from ‘Work order list’

Above example from ‘Completion target RAG scan’

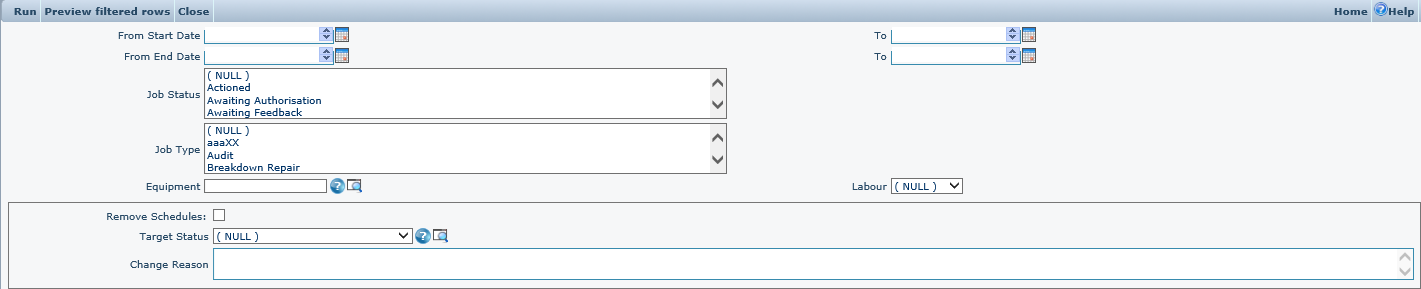

''''Filtered Method

This form contains various filter options to select the work orders that will be changed to the status specified in the Target Status’ value.

The work orders can be selected by, date ranges, current work order status, work order job type, the equipment the work order has been raised against or the primary optimum labour resource on the work order. When the filter criteria have been specified selecting ‘Preview Filtered rows’ from the menu bar will display a scan form containing all the work orders that will be changed by the process. Checking the work orders with the preview option is strongly advised as this process with change the status of all work orders in the system that meet the filter criteria. If you want to append Status Change Reason to Completion Comments of filtered work orders you will have to set system parameter BulkUpdateAppendCompletionComments to true.

The list of work orders should be examined carefully to ensure that work orders that do not required modification are present. If the list contains any work orders that should not be modified then the scan form should be closed and the filter criteria changed.

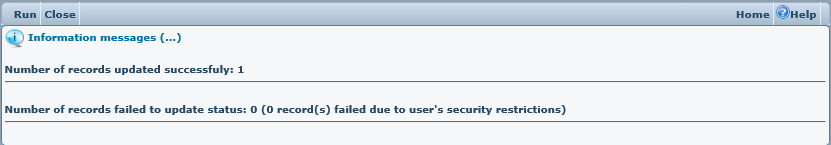

Once the preview list has been examined and found to contain only work orders that are to be modified. The process can be executed by closing the preview scan form and selecting the ‘run’ option form the menu As aforementioned the process will then change the status of any work order meeting the current filter criteria selected on the form to the status specified in the ‘Target Status’ value. Once the process is complete a system message will be displayed stating how many records have been modified and if any failed.

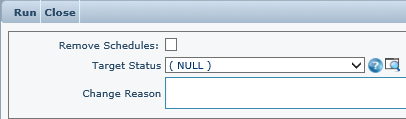

Selection Method

The selection method performs the same function but instead of using a filter on the bulk change form, the work orders that are to be changed are selected from the previous work order scan by clicking the selection checkbox. No preview option is available on the bulk change form. When the ‘run’ option is selected all the selected work orders will be changed to the selected target work order status. If you want to append Status Change Reason to Completion Comments of selected work orders you will have to set system parameter BulkUpdateAppendCompletionComments to true.

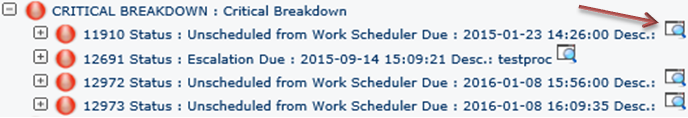

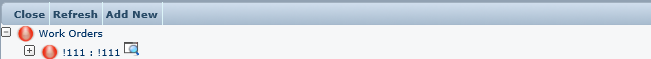

Viewing Work orders from scan and tree views

As with any scan form in the system the details of a work order can be viewed by clicking on the magnifying glass icons that on the same row as the required work order.

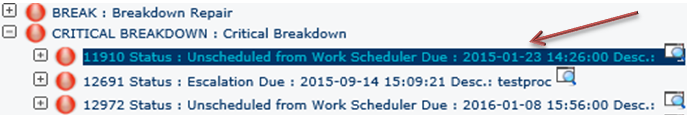

The details of any work order in the structure in a tree view can be viewed by clicking on the magnifying glass next to it

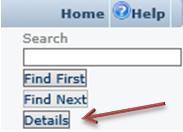

Or by highlighting the work order using a single left click,

and clicking the 'details' button located on the form after that.

RAG Reports

The system contains several RAG views and scans that use colours and icons to indicate the work order state based on due date analysis. There are three ‘states’, ‘Ok’ represented by Green, ‘Concern’ represented by amber, and ‘Overdue’ represented by red. Generally these states are calculated on this basis*. (*Response target scan is calculated on response not completion. These are explained in the respective topics)

Ok

The work order completion date/time date has been populated and its value is less than or equal to the work order due date/time. Or the completion date/time is not populated and the current system date/time is less than the work order completion warning date/time. Basically, if the work order has been completed within the target or it has not been completed but there is still enough time to complete it.

Concern

The work order completion date/time has not yet been populated and the current system time is between the work order completion warning date/time and the work order due date time.

Overdue

The work order completion date/time has been populated and is greater than the work order due date/time or the work order completion date/time is not populated and the current system time is greater than the work order due date/time.

Work Order List

Work Orders >> Work Order List

The most basic of work order scans is the work order list, which provides a simple list of work orders with filtering and completion options.

Work Order Task List

Work Orders >> Work Order Task List

This scan is similar to the work order list however instead of displaying a list of individual work order a list of individual tasks is displayed. So for multi-task work orders the same work order number will appear multiple times, once for each task. Various filtering and task completion options are provided.

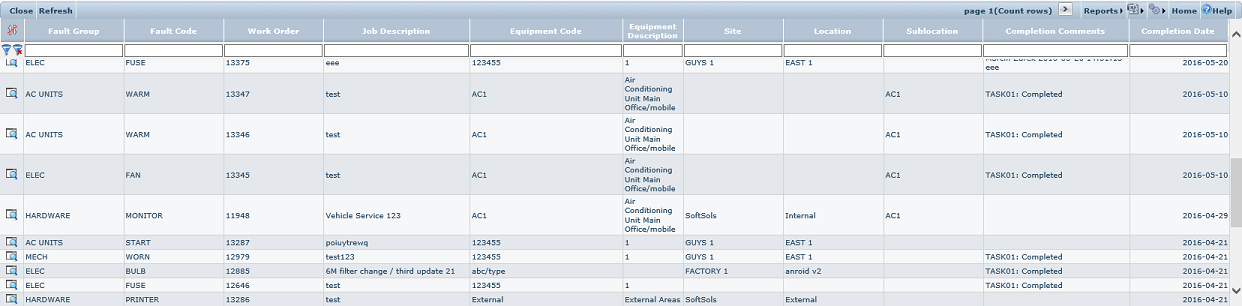

Fault Analysis

Work Orders >> Fault Analysis

The fault analysis scan provides a list of work orders where fault codes have been recorded with filtering and sorting options. A basic fault analysis report is accessible from this form. A much more comprehensive fault analysis report is available in the system form the Reports >> Equipment >> Fault Analysis menu option.

Completion Target RAG Scan

Work Orders >> Completion Target RAG Scan

This scan forms utilises the work order completion target date/time to determine the current condition of a work order.

The condition of the work order can exist at one of three states, ‘OK’, ‘Concern’, ‘Overdue’. This is determined by the system comparing the completion warning date/time (if populated) to the date/time of the server hosting the agility system. The condition indicator is then changed to reflect the status. The completion warning date/time is automatically calculated based upon the work order priority. (Please see priority codes for more information)

The condition is calculated as follows;

Ok

The work order completion date/time date has been populated and its value is less than or equal to the work order due date/time. Or the completion date/time is not populated and the current system date/time is less than the work order completion warning date/time. Basically, if the work order has been completed within the target or it has not been completed but there is still enough time to complete it.

Concern

The work order completion date/time has not yet been populated and the current system time is between the work order completion warning date/time and the work order due date time.

Overdue

The work order completion date/time has been populated and is greater than the work order due date/time or the work order completion date/time is not populated and the current system time is greater than the work order due date/time.

For example;

On a job with a one hour priority on the priority code the completion threshold is set to 15 minutes.

When a work order is then created using this priority, the warning date/time is set to 15 minutes prior to the calculated due date/time.

Before work order is completed :

In this example, on the work order completion target scan form, the work order condition will be displayed as ‘OK’ from 10:41 to 11:26.

When the server system time reaches 11:26 the condition on the scan will be put to a warning state.

Once the due time has been reached on the server the condition state will be changed to overdue.

(for this example: Due Date is 11:41 but because the Grace Period in Priority definition is set to 5 minutes so the value 11:46 will be used)

After work order is completed:

In this example, on the work order completion target scan form, the work order condition will be displayed as ‘OK’ if work order was completed between 10:41 and 11:46 (Due Date 11:41 + 5 minutes Grace Period).

the work order condition will be displayed as 'Overdue' if work order was completed after 11:46 (Due Date 11:41 + 5 minutes Grace Period).

If the on target column is then sorted ascending on the condition (‘On Target’) then the view can be organised so that the concern jobs always appear at the top of the scan.

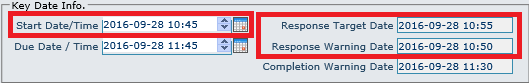

Response Target RAG Scan

Work Orders >> Response Target RAG Scan

This scan forms utilises the work order completion target date/time to determine the current condition of a work order.

The condition of the work order can exist at one of three states, ‘OK’, ‘Concern’, ‘Overdue’. This is determined by the system comparing the response target date/time (if populated) and response warning date/time on the work order to the work order responded at date/time value. The condition indicator is then changed to reflect the status. The response warning and target date/time values are automatically calculated based upon the work order priority. (Please see priority codes for more information)

The work order responded at date/time value is populated with the start date/time of the earliest transaction entered against the work order. This can be a labour, material or cost transaction. For example this could be the work order log on entry.

The condition is calculated as follows;

Ok

The work order responded at date/time has been populated and its value is less than or equal to the work order response target date/time. Or the work order responded at date/time is not populated and the current system date/time is less than the work order response warning date/time. Basically, if the work order has been responded to within the target or it has not been responded to but there is still enough time to respond to it.

Concern

The work order responded at date/time has not yet been populated and the current system time is between the work order responded at warning date/time and the work order response target date/time.

Overdue

The work order responded at date/time has been populated and is greater than the work order response target date/time or the work order responded at date/time is not populated and the current system time is greater than the work order response target date/time.

For example;

On a work order with a one hour priority the priority code is set so that the target response time to the job is ten minutes and a warning is to be produced 5 minutes prior to the target time.

When a work order is created using this priority the warning date/time fields are set accordingly.

In this example, providing that no employee logs onto the job;

When the system time is before 10:50 the status on the ‘work order response target status’ scan will be displayed as ‘Ok’

When the system time reaches 10:50 the target status will then be updated to a ‘concern’ state.

Once the target response time has been exceeded, in this example 10:55 the status will then be updated to ‘Overdue’

These values are also used in the KPI indicators for Response and Completion Targets.

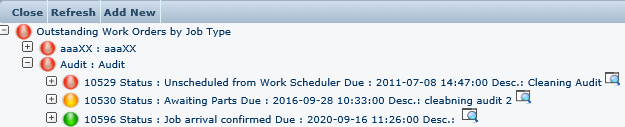

Work Orders by Job Type

Work Orders >> Work Orders by Type

This is a tree view shows all outstanding Work Orders, grouped by Work Order Type and using a RAG indicator to indicate worst case status of work orders within the underlying structure.

Icons are used to indicate the condition of Work Orders within each Job Type Category. This is based on the Due Date Analysis conditions (OK, Concern and Overdue). In the below example the ‘Audit’ work order type is at a ‘red’ condition indicating overdue. This is because although some of the underlying work orders are not at an ‘overdue’ condition, at least one is. So the worst case condition in this example is ‘overdue’.

RAG Report

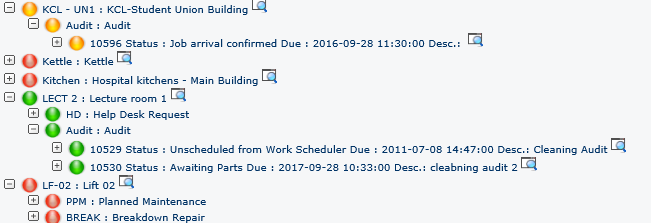

Accessed from Work Orders >> RAG Report

This is a tree view that shows all outstanding Work Orders, grouped into a structure by Equipment and then work order type. It is useful for ascertaining the current state of any equipment item.

Icons are used to indicate the worst case condition at each level within the structure based upon due date analysis conditions (OK, Concern and Overdue). For example from the above extract various things can be determined;

‘Lecture Room 1’ has got outstanding ‘audit’ work but we do not need to be concerned at the moment as the status is ok and ‘KCL Student Union Building’ has also got outstanding audit work which is more pressing in terms of due date analysis. Additionally it can be seen that there are several items at a ‘red’ condition like ‘Lift 02’ where there are planned and breakdown work orders that are outstanding and overdue.

Location RAG Report

Works Orders >> Location RAG Report

This is a tree view that shows all outstanding work orders grouped into a structure by the equipment location, then the equipment item and then the work order type. It is useful for ascertaining the current status of a given site.

Like the RAG report, icons are used to indicate the worst case condition at each level within the structure based upon due date analysis conditions (OK, Concern and Overdue).

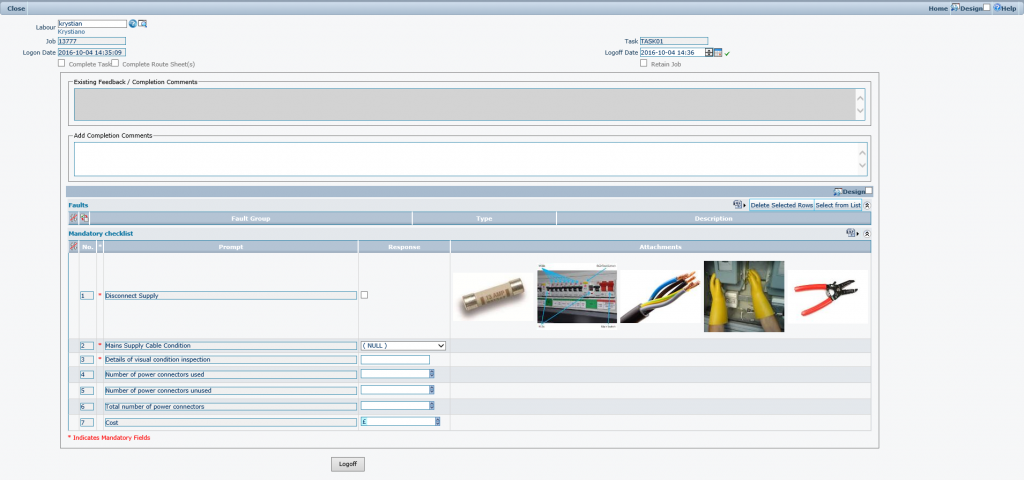

Work Order Log on/off

Work Order Logon/Logoff functions are provided to easily mark the Work Order and task the employee is currently working on. Once the Work Order or task is completed or suspended, employee can easily log off the currently assigned Work Order. Logon/Logoff automatically creates a labour transaction record and calculates the cost based on the time between logon and logoff actions.

Accessed from Work Orders >> Work Order Log on/off

When the Employee Work Orders scan is initially opened, it contains all Work Orders scheduled to the employee currently logged into the system as well as all work orders which have not been scheduled yet but with craft requirements appropriate to crafts assigned to the current employee. Default filtering in this scan form assumes that there is an employee assigned to the current login. If there is no employee assigned to the current login, no records will be displayed.

Logging On

The log on form is accessed by clicking ![]() icon adjacent to the required job.

icon adjacent to the required job.

Field Definitions;

Labour

This is the code of the employee logging into the job. This field is filled in automatically based on the user currently logged in but it can be modified by hand.

Job, Equipment, Task, Craft

Those fields are automatically populated from the task record the Employee is logging into and they cannot be modified on the form.

Logon Date

Date and Time of the Login operation

Existing completion Comments

This text box contains details of any completion comments that may have been previously added.

Mandatory checklist

See how to add checklist results in Work Order Detail under "Checklists" chapter.

“Logon” button

This button triggers “logon” action. If the employee is currently logged into another task, the error message “Employee is logged on to a different task” will appear on the screen and the logon process will fail, as the employee cannot be logged into 2 different tasks in the same time. If this happens, employee should logoff first using other tasks first.

Logging off

“Logoff” button

Logging off from a job is performed using the log off form. Click on the log on/off icon adjacent to the required that the user is currently logged on to. This will open the log off form.

Labour

This is the code of the employee logging off the job. This field is filled in automatically based on the user currently logged in but it can be modified by hand.

Once the labour field is populated a proportion of the remaining fields are auto populated from the job.

Job and Task

Those fields are automatically populated from the task record the Employee is logging off and they cannot be modified on the form.

Complete Task check box

This field is provided to complete the selected task automatically when the logoff process is completed.

Complete Route Sheets check box

This field is provided to allow completing all route sheet items all together with the completing the task if Complete Task check box is checked.

Job Completion comments

This read-only field shows all completion comments entered so far in work order.

Add Job Completion Comments

This field is provided to allow the user to add some completion comments to the work order.

Logon Date

This is filled in automatically and displays the date and time at which this employee logged on to this job.

Logoff Date

This is the recorded logoff date and time. IT will default to now, but can be modified by the user.

Mandatory checklist

See how to add checklist results in Work Order Detail under "Checklists" chapter.

Retain Job check box

This check-box is provided to allow suspending the task temporarily rather than releasing it for other employees to log on. When this check-box is checked and logoff button is pressed, the task remains scheduled to the same employee and the task status is changed to “LOGOFF”. In case when the check box is not checked and the logoff button is pressed, the task is being unscheduled and the task status is changed to “UNSCHEDULED”.

“Logoff from Task” button

This button will commit the log off data to the system and log the employee off from the job.

The log off form also contains a grid when any fault code can be additionally recorded prior to logging off. Any faults recorded here will be recorded against the work order.

To add one or more faults click the select from list button.

This will open a multi select grid of available faults that can be selected.

Click the check box of the fault(s) that need to be added to the work order using the selection check boxes.

Once the selection has been made click the ‘get selected rows’ option to return the selected rows back to the grid.

If any selected faults need to be removed from the grid. They can either be removed at this stage by clicking the check box on the unrequired row and clicking the delete selected rows button, prior to clicking the ‘Log Off’ button. Or they can be removed from the work order later.

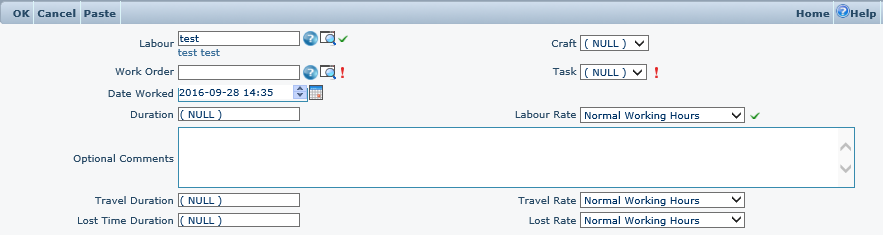

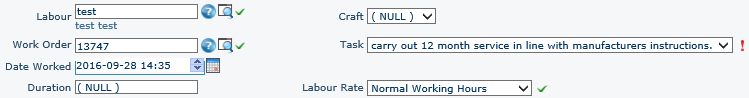

Labour Time Entry (Rapid Time Sheet Entry)

Work Orders >> Labour Time Entry

This form allows time entries to be booked directly to a work order using simple data entry. It is used for the recording of time transactions and does not change the status of the work order.

On initial entry to the form the labour and work order values should be filled out.

Labour

The Labour Resource which has spent the time on the Work Order should be selected from the drop-down list or the help form.

Work Order

The relevant work order should be selected from the help form.

This will auto populate some of the other values. The remaining fields should then be completed where applicable according to the field definitions below.

Craft

As Labour Resources can have several crafts, it is necessary to record in this field the craft under which they carried out the work.

Task

The first task within the select Work Order will be automatically entered in the Task field. This can be changed if necessary via the drop-down list.

Duration

The duration of the activity should be recorded in this field.

Labour Rate

This drop-down list is used to select the applicable Labour Cost rate that should be assigned to this time sheet entry.

Optional Comments

This free-text box allows for any comments regarding the Time entry to be recorded.

Travel Duration

The amount, if any, of time used to travel to the job

Travel Rate

The rate at which travel cost for the above is to be applied

Lost Time Duration

This amount, if any, of lost time to be recorded

Lost Time Rate

The rate at which lost time cost for the above is to be applied.

Selecting ‘OK’ from the menu will save the Time entry against the relevant work order / task.

The Labour transactions recorded against a task can be viewed by clicking on the appropriate task detail icon within the Time / Material tab of the Work Order.

Completing Work Orders and Work Order Tasks

During normal work flow or when completing a work order or work order task, time, materials and other costs can be recorded against work order tasks using various methods within the system. When all the transactions for materials, time and other costs have been entered against a work order or a task it can be completed.

There are different methods in the system for the completion of work orders and tasks;

By using the task completion form

By using the work order completion form

Using the work order detail form in change mode

Directly adding the completed work order

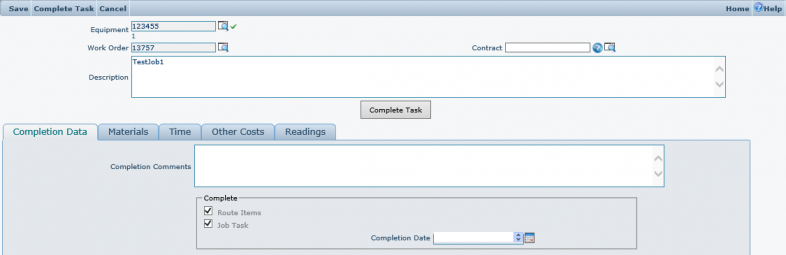

Task Completion form

The task completion form completes a single task on a work order. It does not complete overall work order. The form is accessed form the work order task list scan by clicking the ‘chequered flag icon on the same row as the required task.

The form will open with certain values pre-populated.

The upper part of the form contains the main task detail and is usually pre-populated from the selected task. The lower part of the form contains a selection of tabs where transactions can be added, viewed, recorded and edited prior to completion.

Tabs

Completion

In this tab the completion comments can be added, the date and time which this task was completed.

Materials

Any existing material transactions associated to the task will be detailed here; any additional ones can also be added here

Time

Any existing labour time transactions associated to the task will be detailed here; any additional ones can also be added here

Other Costs

Any existing ‘other cost’ transactions associated to the task will be detailed here; any additional ones can also be added here

Readings

This tab details any reading points associated with the equipment that the current task has been raised against. Reading taken as part of the task can be recorded here.

Once all transactions have been checked and added clicking the ‘Complete Task’ button will complete the task. Although the task has been completed the work order still needs to be completed.

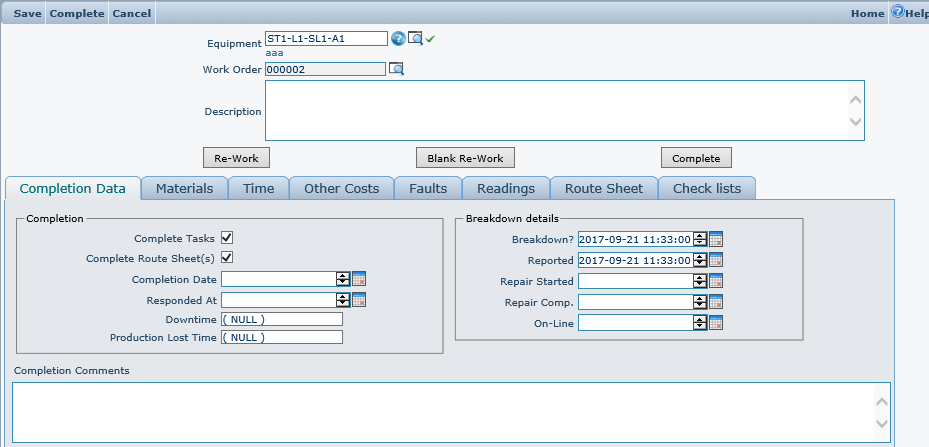

Work order Completion Form

The work order completion form can be accessed from the majority of scan forms by clicking the ‘chequered flag icon on the same row as the required work order.

Although this method can be used to complete multi-task work orders the form only displays details of the main or first task on the work order. If during the completion process details need to be added to multiple tasks it is recommended that completion is done using the work order detail form in change mode.

When the completion form opens the top portion of the form contains pre-populated work order data. The lower portion contains a series of tabs for the recording of transactions against the first or main task on the work order.

Completion data

The completion data tab contains the main completion data about the job, times, comments and breakdown details if the work order was of a break down job type.

Complete Tasks (check box)

If this check box is ticked, then all the tasks in the Work Order will be completed at once. By default, this box is checked. Un-check this box if the Work Order contains multiple tasks which are not completed simultaneously. All tasks must be completed before a Work Order can be completed.

Route Items (check box)

If this check box is ticked, then all the Route Sheet Items in the Work Order will be completed at once. By default, this box is checked. Un-check this box if the Work Order contains multiple Route Sheet Items which are not completed simultaneously. All Route Sheet Items must be completed before a Work Order can be completed.

Down Time

To specify the amount of time the equipment was offline during the repair.

Production Lost Time

This is to specify the overall amount of lost production time which may differ to the down time.

Downtime and production lost time are only accessible when the work order uses a breakdown work order type.

Completion Comments

Details of what was done to repair the item. This should be comprehensive enough for anyone to see and understand the actions taken.

Breakdown Type Work Order Key dates

Breakdown Date

This is the date/time when the breakdown occurred

Reported

This the date/time when the breakdown was reported

Repair Started

This is a date / time that the repair was started.

Repair Completed

This is a date / time that the repair was completed.

On-Line Date

This is a date / time that the Equipment was deemed to be on-line and operational.

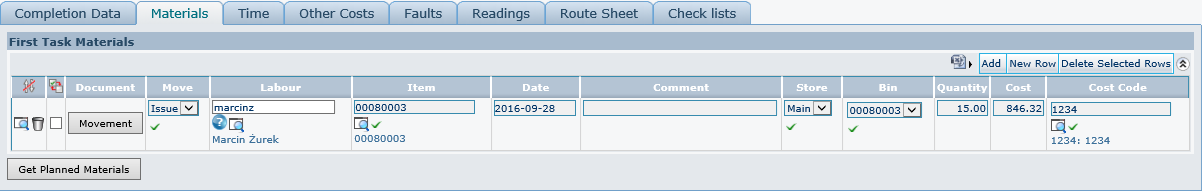

Materials Tab

This screen allows for the addition of items, from the Inventory Stores, that have been used in carrying out the work indicated by the work order. Existing items that have already been added will be displayed.

Move

The type of movement, i.e. an issue or return

Labour

Labour code of an employee if the item was issued directly to an employee.

Item

The Item field is mandatory. Click on the help icon to display a list of inventory items within the Store that was selected in the Movement header. Click on the green tick to select the desired item.

Date

This date represents the date that the inventory items were return or issued.

Comment

This free-text box allows for any comments regarding the inventory item entry to be recorded.

Store

This is the Store from which the inventory item was taken. The default store is always selected in the Store field. This can be amended via the drop-down list within the field.

Bin (Bin Location)

The Bin (Bin Location) records the main Bin details for this movement. Click on the help icon to display a list of Bin Locations that hold the inventory item within the selected Store.

Quantity

The Quantity field signifies the quantity of stock moved in this movement.

Cost

The Cost Value (Line Value) is automatically calculated based upon Quantity x unit cost, representing the total value for this movement.

Cost Code

A cost code against which the material cost is applied.

Once the inventory Movement Line has been populated, click on ok to return to the Inventory Movement record. The Movement is shown in the Movement Lines grid.

For further details on how to input an Inventory movement, please refer to the Inventory Movement section in this document

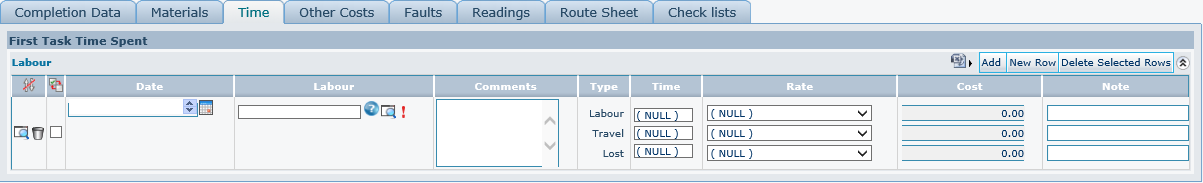

''''Time Tab

Time transactions are recorded for all employees, who have been involved in carrying out the work indicated by the work order and against the main or first task on the work order. Previously added or recorded time transactions against the main or first task on the work order will be displayed here.

Labour

The Labour can be selected from the help scan or entered manually. This represents the Labour Resource against whom time is to be logged against. This does not have to be the Labour Resource who to whom the task was originally scheduled. Multiple time transaction for different or the same employees can be added.

(Above shows new row within time grid)

(Above shows new time transaction entry form, from ‘add button’)

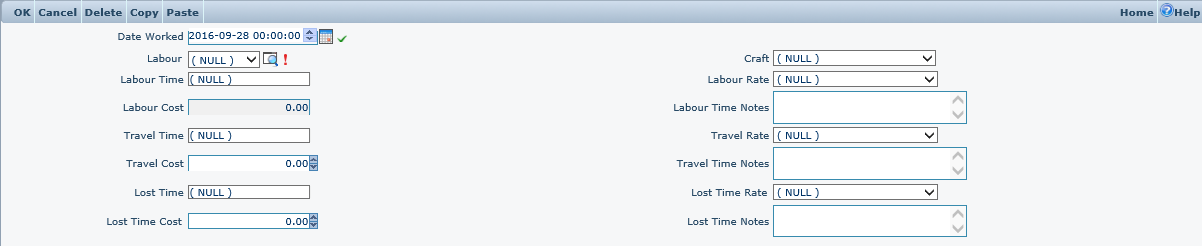

Field Definitions;

Craft

As Labour Resources can have several crafts, it is necessary to record in this field the craft under which they carried out the work.

Date Worked

This is the date when the work against this task was conducted.

Labour Time

Labour time is recorded in hours and minutes and signifies the amount of time the spent working on the task.

Labour Time Notes

This is a free format field to enable any relevant notes to be added.

Labour Rate

The Labour Rate can be selected from the drop down list. This is the Labour Cost Rate that is to be applied for this time allocation.

Labour Cost

The Labour Cost will be calculated automatically based upon values entered in the Labour Time and Labour Rate fields. The Labour Cost cannot be manually adjusted.

Travel Time

Travel time is recorded in hours and minutes and signifies the amount of time the employee spent travelling before being able to begin work on the task.

Travel Rate

The Travel Rate can be selected from the drop down list. This list is populated with the Travel Pay Rates and represents is the Rate that is to be used for this time allocation.

Travel Cost

The Travel Cost will be calculated automatically based upon values entered in the Travel Time and Travel Rate fields. The Travel cost cannot be manually adjusted.

Travel Time Notes

This is a free format field to enable any relevant notes to be added.

Lost Time

Lost time is recorded in hours and minutes and signifies the amount of time that was lost whilst working on the task. An example of lost time is where an employee has had to wait in order to gain access to a building.

Lost Time Rate

The Lost Time Rate can be selected from the drop down list. This list is populated with the Lost Time Pay Rates and represents is the Rate that is to be used for this time allocation.

Lost Time Cost

The Lost Time Cost will be calculated automatically based upon values entered in the Lost Time and Lost Time Rate fields. The Lost Time cost cannot be manually adjusted.

Lost Time Notes

This is a free format field to enable any relevant notes to be added.

Labour Time can be allocated against tasks by clicking on the Add button. This will open the Time Entry Screen (as described in the section Labour Time Entry (Rapid Time Sheet entry) in a previous section of this document).

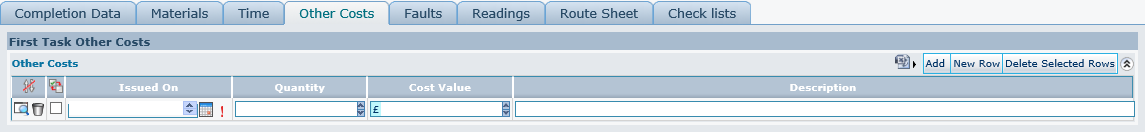

Other Costs Tab

This screen allows for the addition of other costs that have been incurred in carrying out the work indicated by the work order. Other cost transactions actions previously recorded against the main or first task of this work order will be displayed here.

(Above shows new row within time grid)

(Above shows new time transaction entry form, from ‘add button’)

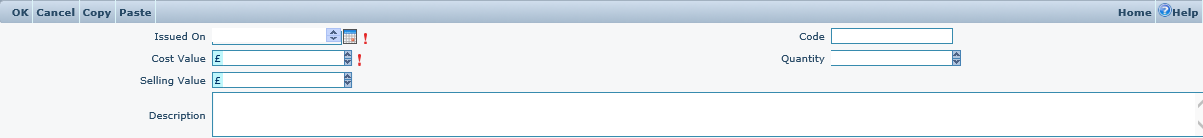

Field Definitions;

Issued On

Enter the date that the cost was accrued.

Quantity

Enter the quantity involved.

Code

This is a free text field to provide a code for the cost.

Description

This is a free text field to provide a description for the cost.

Quantity

Enter a relevant quantity, if appropriate.

Cost Value

Enter the actual cost in this field.

Sell Value

If the cost is to be re-charged, enter the selling value in this field.

Faults Tab

Any fault for this work order can be record within this tab. Any faults previously recorded against this work order will already be displayed here.

To add faults click the select from list option. This will open a multi select grid of available faults that can be selected. Click the check box of the fault(s) that need to be added to the work order using the selection check boxes.

Once the selection has been made click the ‘get selected rows’ option to return the selected rows back to the grid.

Readings Tab

This tab details any reading points associated with the equipment that the current task has been raised against. Reading taken as part of the task can be recorded here.

For more information on adding readings please refer the ‘equipment reading point’ topic in the equipment chapter.

Route Sheets Tab

If the work order contains route sheets they will be listed here. All of the route sheet items can be marked as complete in one action by checking the ‘Complete Route Sheets’ flag on the Work Order Completion Tab.

If completion comments are required for the individual route sheet items, additional comment cn be added in the comment completion section for each route sheet.

Feld Definitions;

Item Order

The Item Order will be generated automatically however this can be manually adjusted to record the order in which the route sheet items should be dealt with.

Equipment

This is the equipment code of the item to be added to the list.

Description

The full descriptive name of the equipment item

Instructions

Instruction specific to this individual route sheet item

Costing Share (%)

The Costing Share field is used to determine what percentage of the overall Work Order cost is allocated against the Route sheet item. For more information on costing share please refer to the advanced tab route sheet section of the work order detail topic.

Completed?

Check this flag to signify that the Route Sheet item is completed.

Completed Date

This is the date that the Route Sheet Item was completed.

Completion Comments

This free text field allows the user to enter completion notes regarding the Route Sheet Item.

Completing the work order

Once all data has been entered the work order can be completed by clicking the complete button on the form or selecting the complete option from the top menu bar. If any mandatory details are missing these will be highlight to the user at the top of the form.

The details entered on the form can be saved without completing the form by using the save function.

Completion with work order detail form

The work order detail form provides the most comprehensive options for data entry when completing the work order, as any aspect of the work order can be modified for all tasks. On opening the work order detail form, enter change mode by clicking on the change option in the menu bar.

Completion is performed by accessing the completion tab. For details and information about all other form content please refer to the [ work order detail] section of this document.

Completion Tab

This tab contains the options required for completing this work order. The tab function is the same as defined for the ‘completion tab’ in the [ work order completion form] section.

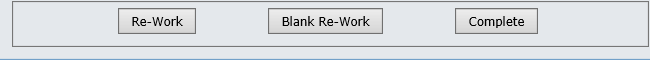

Re-Working of Work Orders

In situations where part of a Work Order has not been completed, or if additional work has been highlighted by an engineer when the work order has been completed, an additional follow-on work order can be created from the existing work which can replicate the majority of relevant details.

There are two types of Follow-on Work order available:

- Re-Work-work order

- Blank Re-Work work order

A Re-Work work order will create a copy of the current work order, copying across all fields.

If the Blank Re-Work on is selected a blank form will be displayed with just the ‘create from’ field populated

Both types of follow on work order can be created through the Work Order Completion Tab on the work order completion form or the work order detail form by clicking on the appropriate button:

In the example below, a follow on work order has been created for WO/1048. This has copied all the data into the new Work order. All grid details are also copied over; these should be checked and deleted if not appropriate.

In either case, a new Work Order Code will be generated when the new re-work order is created.

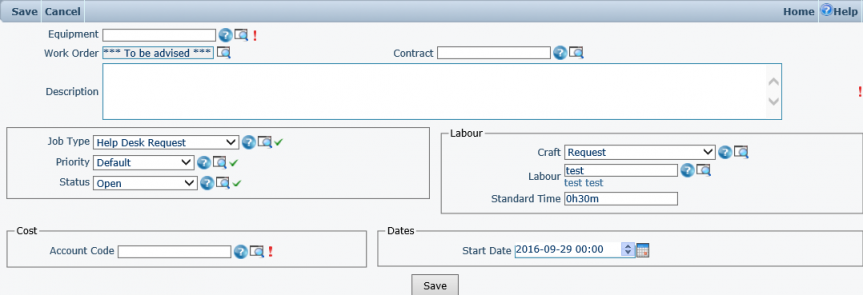

Quick Adding a Completed Work Order

Work Orders >> Add Completed Work Order

There will be occasions when it is more important to carry out a repair than to spend valuable time accessing Agility and adding a Work Order before the work can be carried out. Functionality exists that allows details of a single task work to be added, along with any costing after the repair has been carried out.

The initial form captures required detail on the work order and task. This is the usual mandatory information required when adding a Work Order. Once all the details have been entered then the save button should be clicked to create the work order and assign a job code.

Once the save is clicked the [ work order completion form] automatically opens. Processing then the same as defined in that section.

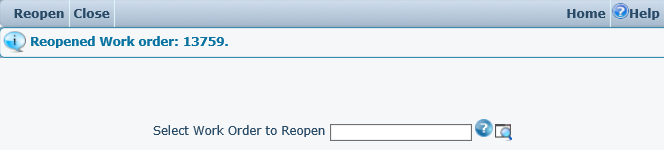

Re-Opening Completed Work Orders

Work Orders >> Re-Open Completed Work Orders

Functionality has been provided for the event that a complete work orders needs to be re-opened. Once this has been done the work order can then be edited.

Once the form has been opened simply enter the work order number, or use the help to locate and select the required work order. Then click the ‘reopen’ option from the menu bar.

When the work order has been re-opened a message will be displayed below the menu bar.

Cancelling Work Orders

Work Orders >> Cancelling Work Orders

Functionality has been provided for the event when work order needs to be cancelled. By selecting special work order status, cancellation process is started.

Depending of system parameter "ProcessMngt\\Job\\CancellWithCosts" process can be aborted by validation checking if there are any costs registered within work order or if they not balance to zero costs. It allows users to cancel work order even if costs have been entered. In such a case user has to enter the same costs again with negative values to balance them to 0.